In the organic waste gas treatment system, the valve switch controls the flow rate, on-off and direction of the pipeline medium, while the automatic control valve replaces manual operation with driving energy to realize remote automatic control, and drives the valve under the action of the control signal to improve efficiency and improve efficiency. Accuracy is a key equipment in the exhaust gas treatment automation system. Below we mainly briefly describe the valve classifications often used in the organic waste gas treatment industry and the commonly used electric and pneumatic methods for scholars' reference.

First of all, we know that the valves commonly used in a complete RTO-based organic waste gas treatment system include poppet valves, high temperature valves, regulating valves, switching valves and solenoid valves, etc., precisely because they are responsible for accurate and reliable in the system. It is a key task, so it is very important to have a deep understanding of them and the correct selection.

1. Classification of valves

1. According to the different driving energy

①Mainly electric and pneumatic

Electric valve: use drive motor as power

Pneumatic valve: uses compressed air as power

②Other power sources: hydraulic (using hydraulic oil as power); electromagnetic drive (relying on electromagnetic force to drive the iron core to move and reset); gas-liquid linkage, electro-hydraulic linkage, etc.

2. According to the different operation modes of the valve

① Straight stroke: the valve core moves up and down in a straight line (straight-through single-seat valve, angle valve, sleeve valve)

② Angular stroke: Partial rotation, the switching action is completed by rotating the valve core from 0 to 90° (butterfly valve, ball valve)

③Multi-turn: the valve stem is in the form of spiral motion, which is converted into linear motion through rotation (gate valve, globe valve)

3. Control purpose

①Switch type: control the valve to open and close two positions

②Regulation type: control valve opening, closing and any intermediate process

2. Electric and pneumatic valves

1. Configuration combination of two complete sets of valves

①Electric: electric actuator + valve

②Pneumatic: switch type: solenoid valve + pneumatic actuator + valve + limit switch

Adjustment type: positioner + pneumatic actuator + valve

The above items, except the valve body, can be called valve accessories.

2. The difference between pneumatic valve and electric valve

①The electric valve uses an electric actuator to control the valve, and the pneumatic valve is a valve driven by compressed air

②The pneumatic valve is faster than the electric valve. The electric valve is used for both manual and electric, while the pneumatic valve is used for both manual and pneumatic, but the price is more expensive.

③ Electric valves are used in places with large pipe diameters, and pneumatic valves are difficult to achieve, but the stability of electric valves is not comparable to that of pneumatic valves, and the switching speed is slow and the actuator takes a long time to cause tooth jamming. However, the switching speed of the pneumatic valve is faster under a stable air source.

④The electric valve is slow, and there are not many brands that can achieve explosion-proof; the pneumatic valve moves quickly, and the explosion-proof price is relatively lower than that of the electric valve, but if it is equipped with accessories of a big brand, the price will be more expensive than the electric valve.

3. Advantages and disadvantages of pneumatic valve and electric valve

Electric valve

Advantages: good effect on liquid medium and large diameter gas, not affected by climate and air pressure.

Disadvantages: Not suitable for wet environments, slow switching speed.

Pneumatic valve

Advantages: good effect on gas medium and small diameter liquid, more convenient maintenance, fast switching speed.

Disadvantages: affected by air pressure fluctuations. For example, in the winter in the north, it is easily affected by moisture in the air, causing the transmission part to freeze and not move.

Usually in the RTO system, we require the valve to act quickly, and usually choose the pneumatic valve. In addition to the valve mechanical body, the key control parts of pneumatic valves, such as response time, failure rate, accuracy, etc., depend on pneumatic accessories. Commonly used pneumatic accessories include the following: positioner, solenoid valve, pneumatic actuator and so on.

3. Pneumatic valve accessories

1. Locator

The positioner is the main accessory of the control valve. It takes the stem displacement signal as the input feedback measurement signal and the controller output signal as the setting signal for comparison. When there is a deviation between the two, the output signal to the actuator is changed. , make the actuator act, and establish a one-to-one correspondence between the valve stem displacement and the output signal of the controller. Therefore, the positioner constitutes a feedback control system that takes the valve stem displacement as the measurement signal and the controller output as the setting signal. The manipulated variable of the control system is the output signal of the positioner to the actuator.

2. Solenoid valve

There is a closed cavity in the solenoid valve, with through holes in different positions, each hole is connected to a different oil pipe, the middle of the cavity is a piston, and the two sides are two electromagnets. At the same time, by controlling the movement of the valve body to open or close different oil discharge holes, and the oil inlet hole is normally open, the hydraulic oil will enter different oil discharge pipes, and then the piston of the oil cylinder is pushed by the pressure of the oil, and the piston is again Drive the piston rod, and the piston rod drives the mechanical device. In this way, the mechanical movement is controlled by controlling the current on and off of the electromagnet. In principle, the solenoid valve is divided into a direct-acting solenoid valve, a step-by-step direct-acting solenoid valve, and a pilot-operated solenoid valve. The solenoid valve is mainly used for reversing or Air flow interruption.

So what is the meaning of the two-way three-way and two-way five-way we usually say? The two positions are open and closed, the three-way is one air source, one outlet and one exhaust, and the five-way is one air source, two outlets and two exhausts. The three-way is equipped with a single-acting cylinder, and the five-way is equipped with a double-acting cylinder.

3. Pneumatic actuator

Pneumatic actuators are actuators that use air pressure to drive open, close or adjust valves, also known as pneumatic actuators or pneumatic devices, but they are generally called pneumatic heads. Pneumatic actuators are sometimes equipped with certain auxiliary devices. Pneumatic actuators can also be divided into two types: single-acting and double-acting: the switching action of the actuator is driven by the air source, which is called DOUBLE ACTING. The SPRING RETURN (single-acting) actuator is replaced by a spring at one end, which has a reset function.

The meaning of single-acting actuators: When a fail-safe position (FO, FC) is required, single-acting actuators can guarantee normally open or normally closed states

Single-acting pneumatic actuator, the meaning of normally open and normally closed? What is air opening and air closing?

Single-acting actuators, when they are open without ventilation, are called normally open; when they are closed without ventilation, they are normally closed.

Air On: Ventilation is on. Air lock: ventilation closed

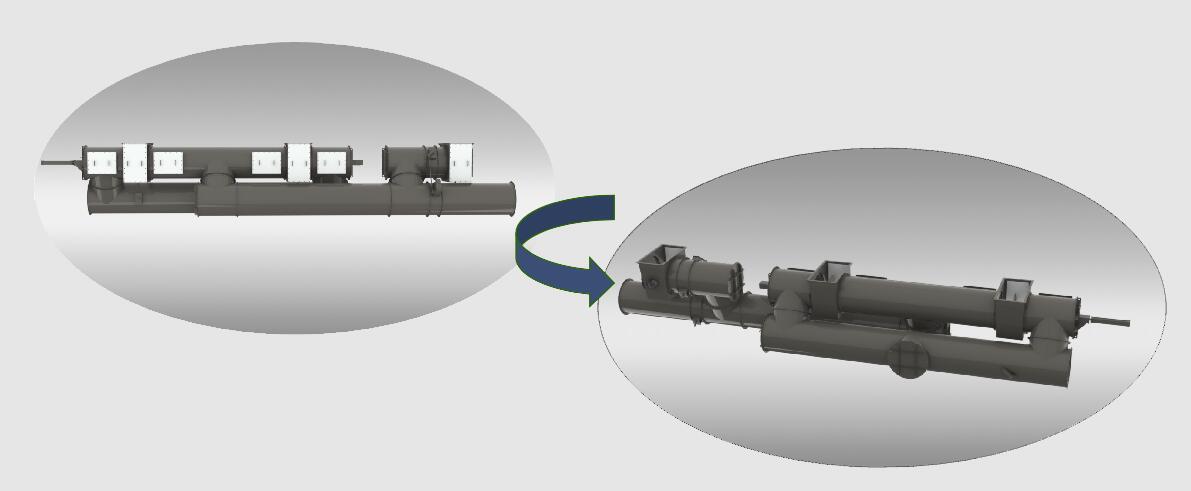

Ausi Environmental Protection adopts unique valve technology for the entire rto equipment, with only two actuators, the structure is simple and easy to maintain and maintain, and even the switching speed of the valve is less than one second. The valve is equipped with an active sealing device, which automatically compensates for the leakage of the sealing material due to fatigue loss. Combining the functions of the third tower, the processing efficiency can reach 99.5%, and the efficiency is balanced. Compared with the traditional three-tower rto, the fluctuation is small.