MICRO BUBBLE-SCRUBBER SYSTEM

Product Description

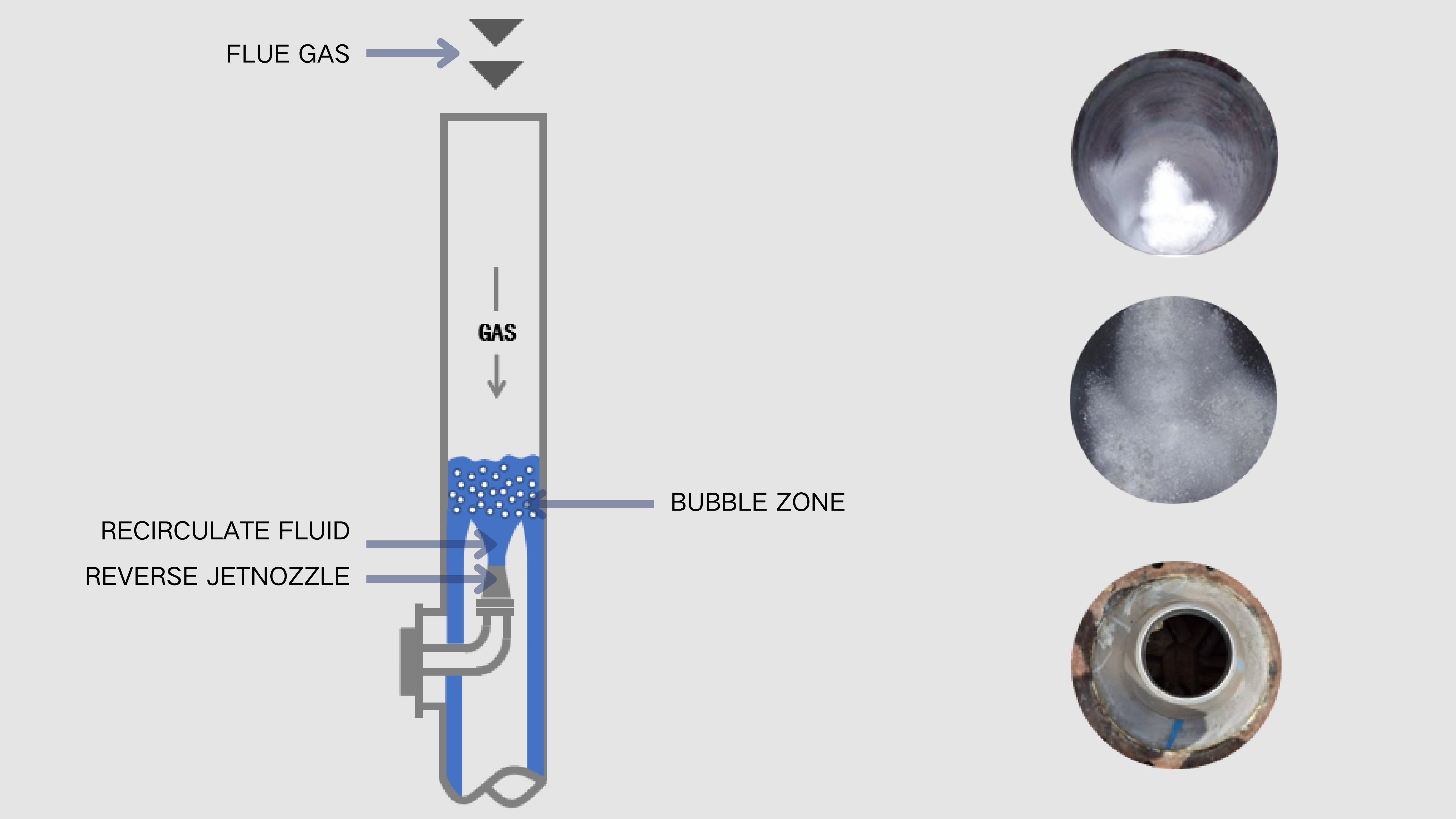

MECHANISM Through non-throttle reverse nozzle, the solution jet into scrub tube reverse against the flue gas, and the gas collides with the liquid, forming a strong turbulent zone in the gas-liquid interface area. The fluid momentum reaches equilibrium, the gas and liquid are in close contact to produce a stable turbulent bubble zone. The bubble zone floats in the airflow and rises and falls with the relative momentum of the gas and liquid phases.

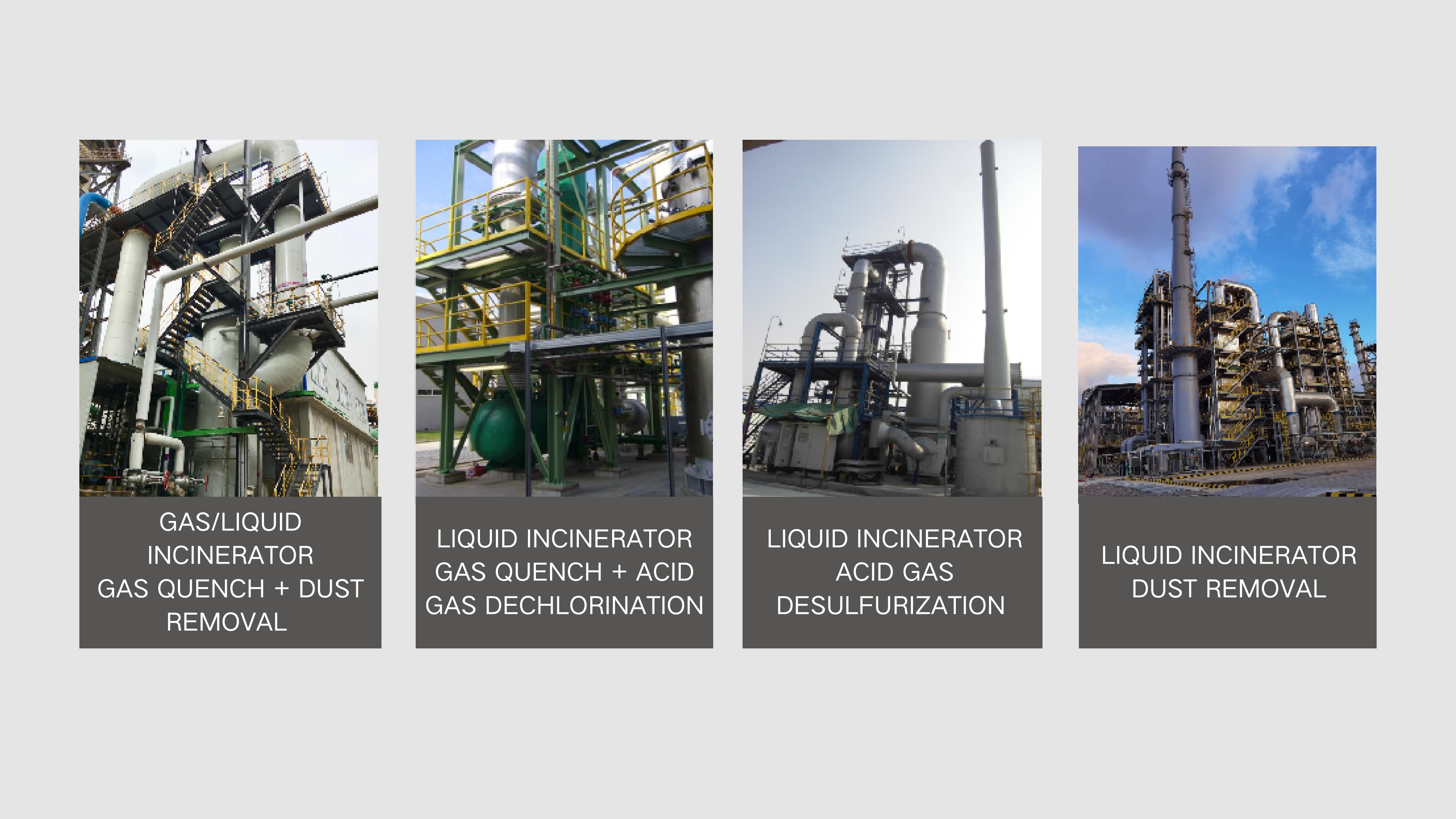

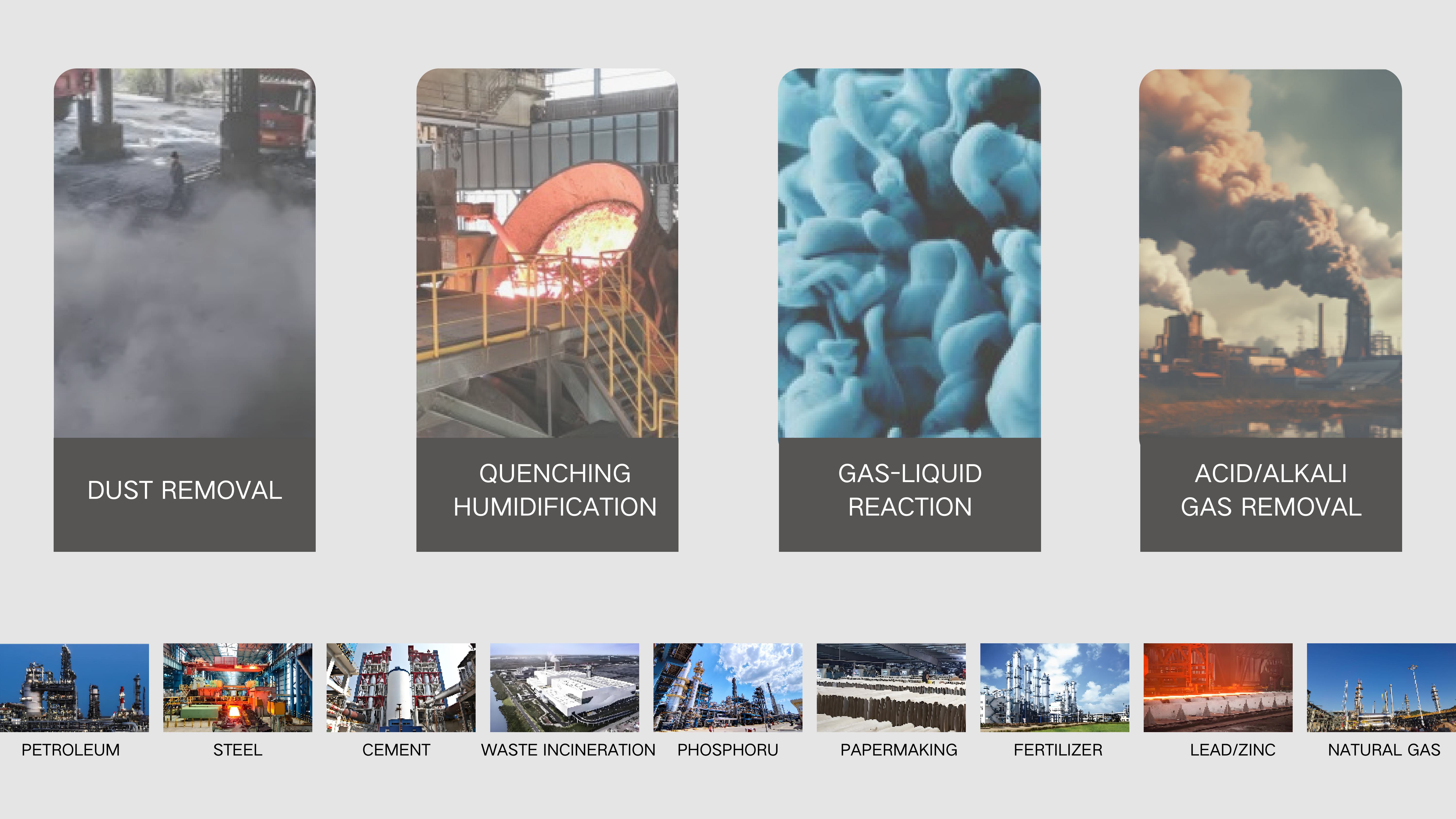

APPLICATION & INDUSTRIES

DESCRIPTION

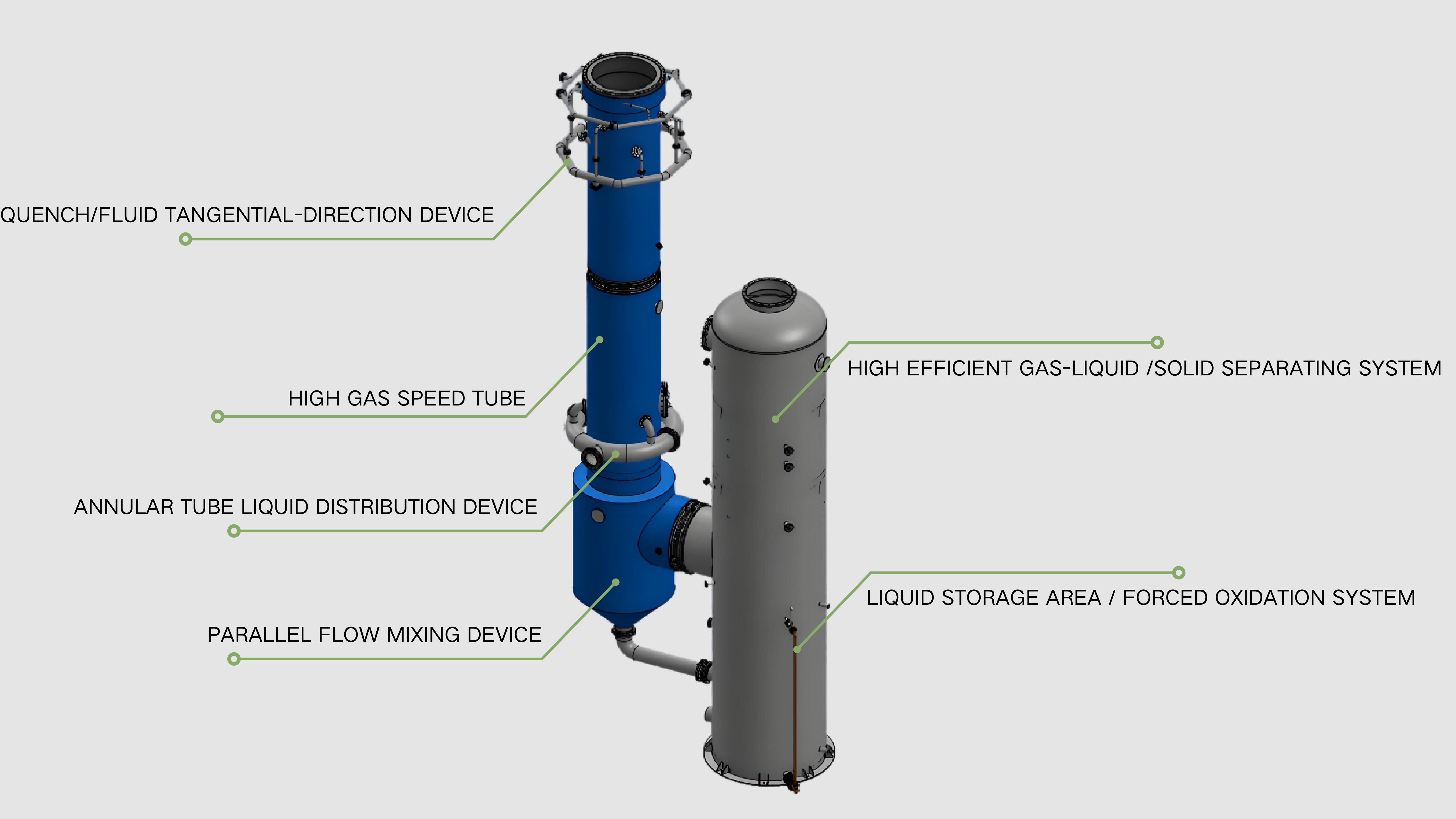

STRUCTURAL

lGAS DISTRIBUTION DEVICE / WATER-SAVING DEVICE

lCONDENSING GAS-LIQUID SEPARATION DEVICE (NO FLUSHING)

STRUCTURAL

Turbulent bubble flow / wall protection / full utilization of evaporation latent heat

The maximum mixing density in limited volume

1s achieve the saturation temperature to avoid the formation of dioxins

Reduces tube diameter and occupied area effectively

No internal design to ensure smooth gas path

Large effective reaction area

High solid content solution can be handled (max 20%)

High viscosity dust can be removed

Viscous solution can be handled

None-atomized solution, lower mist entrainment

High-efficiency gas-liquid / sub-micron particle removal device

Forced oxidation device

Gas distribution device / water-saving device

Condensing gas-liquid/solid separation device (no flushing)

TYPICAL PROCESS FLOW OF DUSTY FLUE GAS ULTRA-LOW EMISSION

High purification efficiency, exhaust emission<10ppm

Less equipment and piping, instrumentation, pumps, etc.

Compact system, small footprint

PROCESS CHARACTERISTIC

High removal efficiency, particle size>5μm can be removed

Less equipment and piping, instrumentation, pumps, etc.

Compact system, small footprint.

30%~50% less discharge compares to traditional scrubber.

PERFORMANCE

Higher gas volume can be treated under the same space scale

Ability to adapt 50%~120% fluctuation

High viscosity dust can be removed

Viscous solution can be handled

Simple operation with minimal controls

Particle size>2.5μm can be removed

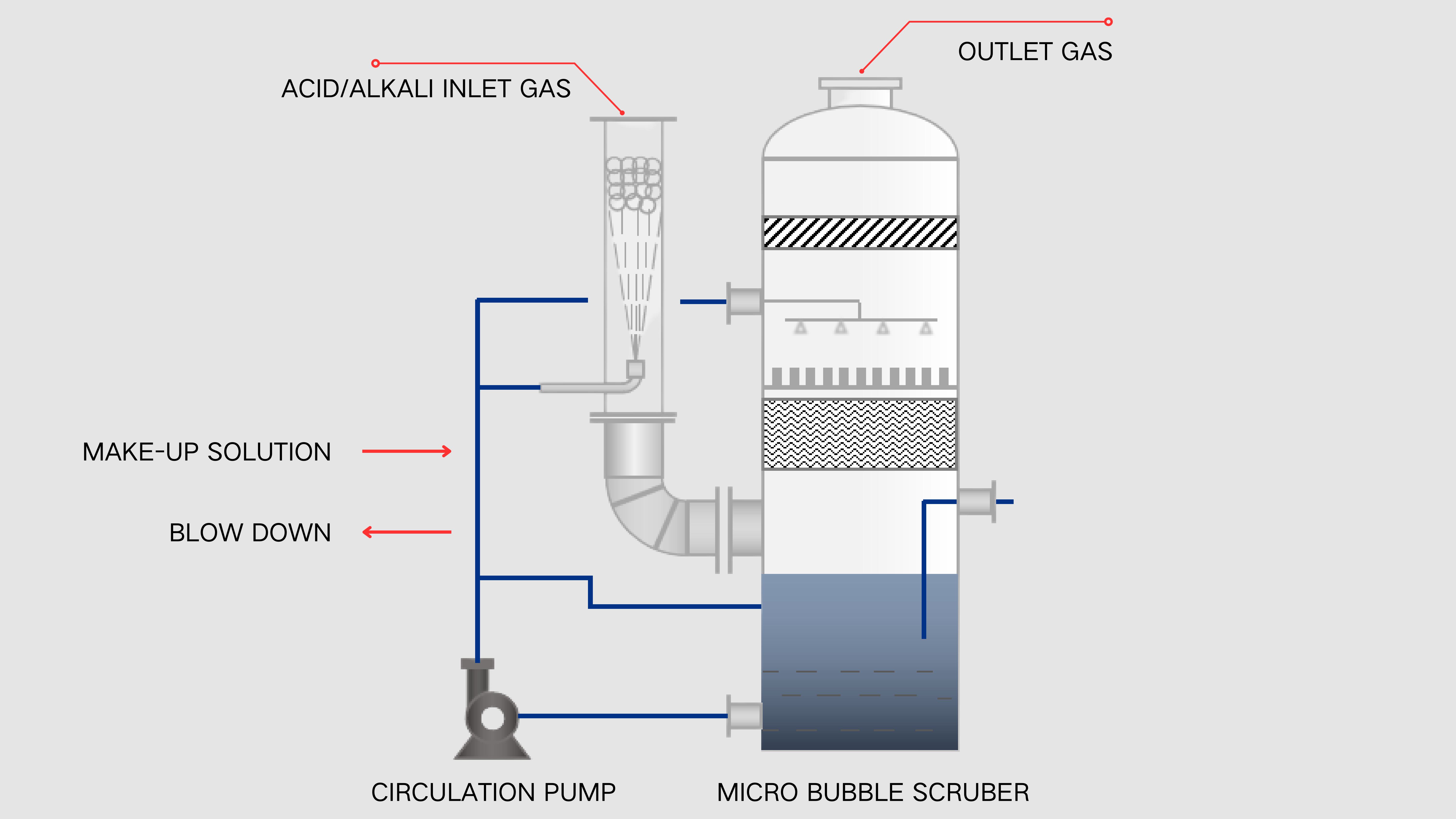

LITHIUM IRON PHOSPHATE PRECURSOR PHOSPHORUS FLUE GAS SYSTEM

Risk of inspection and maintenance(Contain toxic CO)

Low recovery of phosphorus

Less floor area (4 stages to 2 stages)

Less maintenance, more safety for operator

SULFUR RECOVERY UNIT FLUE GAS SYSTEM

Strong sulfuric acid corrosion

Easy blocked pipelines and nozzles of spray tower

Overall cost is reduced by 36 %

Moderate resistance promotes SO3 removal

Outlet SO2 concentration<10mg/m3

POLYSILICON SLURRY HYDROLYSIS FLUE GAS SYSTEM

Sampling port spraying solution easy to hurt operator

Effectively relieves the spray of sampling port

Emission dust concentration<15mg/m3

Emission HCI concentration<10mg/m3

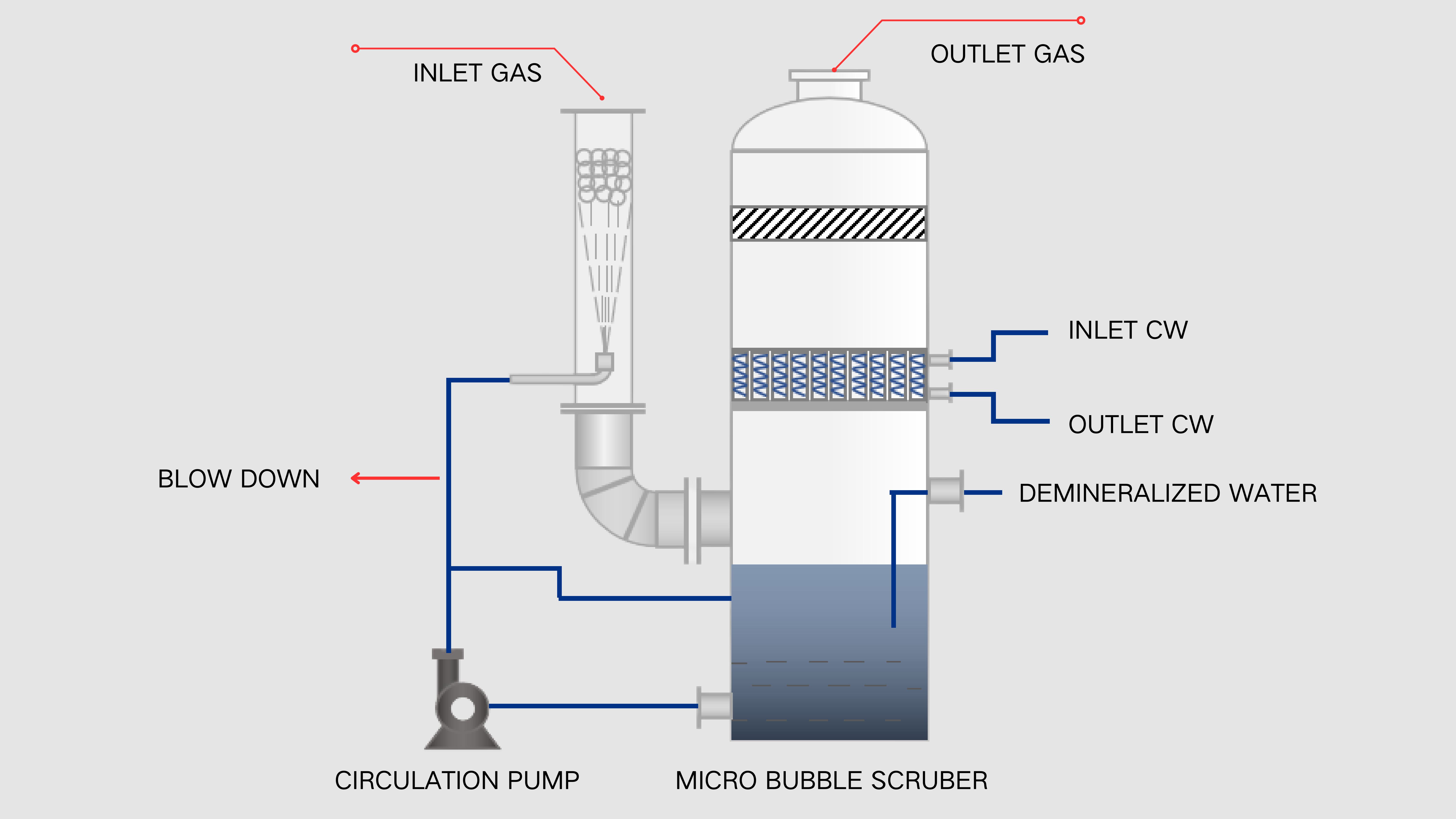

CCUS CO2 flue gas purification and waste heat recovery system

High energy consumption of cooling system

Less floor area

50~150 % system load regulation ability

Flue gas temperature after condensation<40℃

REFERENCE