The fan is the key equipment in the RTO equipment, and it determines the safety production and economic benefits of the entire system. Today, the editor of Ausiyi Environmental Protection elaborates and explains from the type and principle of the fan required by RTO and the perspective of explosion protection.

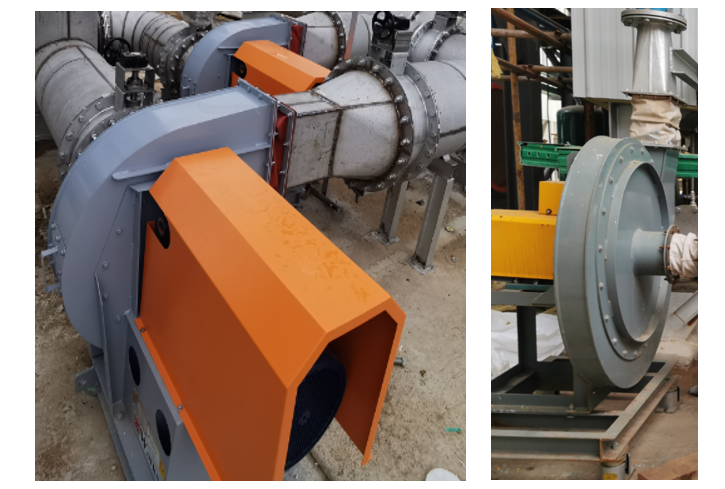

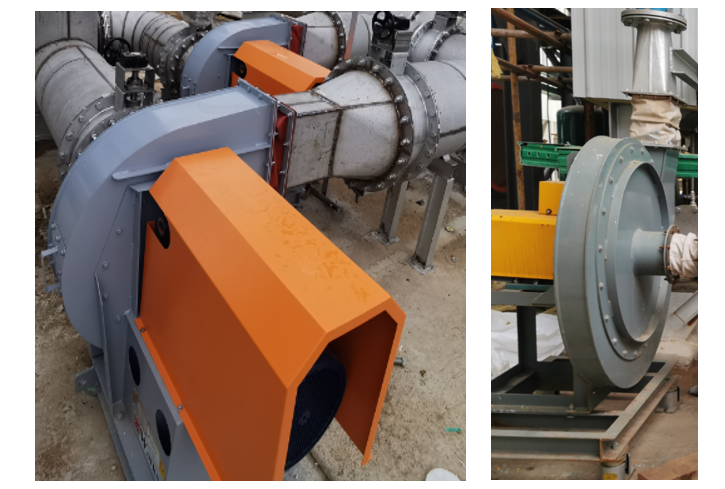

For RTO systems, our commonly used fans include centrifugal medium and high pressure fans, and axial flow medium and high pressure fans. According to the material, it can be divided into metal fans and non-metal fans. The commonly used metal fans are carbon steel, SS304, SS316L, dual-phase steel, etc., and non-metal fans are generally FRP, static-conducting FRP, PP, etc. In the RTO system, fans are divided into the following categories: fans that contact exhaust gas and fans that do not contact exhaust gas. Among them, the fans that contact exhaust gas include main pipeline lead, supply fan and relay fan, and those that do not contact exhaust gas include combustion-supporting fans and back-purging fans. , Anti-leakage fans, etc. Generally, the material selection of the fan that contacts the exhaust gas needs to be selected and designed according to the components and characteristics of the exhaust gas. The fan without contact with the exhaust gas only needs to be designed and selected according to the total pressure and air volume of the fan.

Fan is a general term for gas compression and gas conveyor machinery. It is a machine that converts rotating mechanical energy into gas pressure energy and kinetic energy and transports gas out. It usually has the following parameters that need to be determined:

1. Flow, including air volume and standard air volume;

2. Pressure, inlet and outlet static pressure, fan static pressure, full pressure, boost;

3. Gas medium, including temperature, humidity, density, dust content and gas components;

4. Speed;

5. Output power, generally expressed in KW.

In the RTO system, we usually calculate the pressure loss of the pipeline and equipment in the system first, as the full pressure of the fan, and the air volume is calculated according to the exhaust gas flow of the exhaust gas collection system of the whole plant, so that the full pressure of the induced draft fan of the RTO system can be determined. Of course, when selecting a fan, a margin of 1.05-1.2 needs to be considered, because the selected fan must meet the system requirements when running at full load. However, some domestic first-line fan manufacturers have taken this factor into account and integrated it into the selection software, you only need to input the environmental conditions and process conditions.

So how exactly do you determine air volume and pressure? First of all, it is necessary to determine the upper limit of the wind speed or the number of air changes according to the HVAC regulations of the relevant industry. After the determination, the exhaust gas flow rate is determined according to the exhaust gas emission at the pollution source discharge point and the size of the pollution source space, which is what we call the fan air volume; second, according to the equipment and Pipeline pressure loss, to determine the pressure of the fan, here is what is the pressure of the fan.

In the RTO system, in order to normally lead the organic waste gas (VOCs) to the RTO treatment boundary area and transport the treated clean air to the chimney for discharge, it is necessary to overcome the pressure loss of the entire system pipeline and equipment, and the fan must produce these pressures. The pressure of the gas is divided into three forms: static pressure, dynamic pressure and total pressure. The pressure that overcomes the aforementioned air supply resistance is called static pressure. Static pressure is the pressure of the gas acting on the surface of the object parallel to the airflow. The hole is measured; the kinetic energy required in the gas flow is converted into the form of pressure as dynamic pressure.

pt=pv²2

where Pd - dynamic pressure

ρ - density of gas (kg/m³)

v - velocity of gas (m/s)

The total pressure Pt is the algebraic sum of dynamic pressure and static pressure, namely

Pt=Pd+Ps

In fact, in the RTO system, in addition to paying attention to the fan pressure and air volume, the explosion-proof of the fan is also another top priority, because the RTO is a high-temperature oxidation device, and the treated medium itself is flammable, explosive, toxic and harmful organic compounds. There is a certain danger, and the explosion-proof fan has become one of the most basic safety measures. The fan motors used in the RTO system generally choose explosion-proof motors. In addition to the explosion-proof motors, the fans themselves need to be treated without sparking. For example, metal fan impellers should be made of alloy materials, and the bellows should be treated without sparking. Non-metallic fans must be made of non-metallic materials. Static conductive material, otherwise static electricity will bring great hidden dangers.

The fans in the RTO system are basically running continuously. It is necessary to pay attention to lubrication and cooling, and to lubricate and maintain them regularly. Taking the lubrication cycle of a certain brand fan and the amount of water in and out as a reference, it is necessary to ensure the stable and continuous and efficient operation of the RTO induced draft fan to ensure that the enterprise economic benefits.

In the RTO system, when the fan transports high-concentration VOCs, explosive gas, high-concentration dust, ultra-fine particle materials, toxic and irritating odor gases, in order to prevent the leakage of these gases, it is recommended to select low leakage or zero leakage. Optional packing seal and above shaft seal, zero leakage is best equipped with compressed air seal, and good shaft seal. In the API industry, due to the characteristics of waste gas components, we recommend that the system be designed according to negative pressure, which can avoid the escape of toxic and harmful gases, and avoid the safety hazards of operation and maintenance personnel and enterprises.

To sum up, the RTO system mainly includes the main fan, the rear induced draft fan, the combustion-supporting fan, the back-purging fan, as well as the drying fan and the adsorption fan. Both the RTO main fan and the rear induced draft fan are equipped with frequency converters, and the fan is linked with the pressure in the pipeline to ensure that the fan maintains the pipeline to meet the process. The fan adopts explosion-proof fan, variable frequency motor, and the rated frequency of the motor is 50Hz. During the operation of the system, the fan frequency can be automatically adjusted according to the change of the air volume, and the fan air volume can be adjusted to save energy and reduce consumption, and ensure the stability of the user-wide production line. In addition, the RTO operation and maintenance inspection personnel need to regularly maintain and maintain the fans according to the on-site usage. They must ensure that the most reasonable fan air volume and full pressure are selected according to Party A's process conditions, supplemented by regular maintenance operations. , the whole system can run safely, stably and efficiently.